Five Key Causes of Delay in Data Centre Projects and How to Rectify Them

-

octobre 01, 2024

-

Construction delays can be a huge headache for project stakeholders, especially when they are not properly planned for. Whilst the root cause remains the same across project types, part two of this article series is tailored to delays in data centre projects and how to rectify them. This article will be of special interest to Contractors or Claims Managers in the Construction Industry.

The location, scale and complexity of construction delays can present unique challenges for data centre projects. These can occur during the design, construction, commissioning and close-out phases and can be managed by optimising the construction programme.

Finalisation and Coordination of Design

The late finalisation of design, design updates or modifications to the original design can cause knock-on delays to the construction of the works. Design changes may be driven by evolving technology, client requirements, consideration of upgraded external infrastructure or unforeseen issues. Implementing design changes can be a real problem on complex projects like data centres, particularly when one (seemingly isolated) change at one location within the building affects several other areas and work packages.

By way of example, an admin room, technical room, or main equipment room includes highly technical components and functions as ‘the brain’ of a data centre. An architectural change in these rooms, such as a change in equipment sizing or adjustment of room dimensions, could affect the Mechanical, Electrical and Plumbing (“MEP”) and wiring of the entire room. This change would also affect other work items such as the systems installation and security recognition devices of the room doors. The addition of further equipment may result in a review of the heating, ventilation, and air conditioning (“HVAC”) system to ensure temperature control of the room. There may also be delays within the final testing and certification processes given the complexity of the systems and technologies incorporated.

The highest delay risk of design changes relates to elements of construction that are at the start of the project or are relied upon for procurement of long lead-in time materials and equipment. This is a common delay within the construction of data centres.

To manage design within the construction programme, activities or milestones should stipulate dates for when the designs should be finalised. Consideration should also be given to the time required for design development and coordination following design finalisation. Any progress-updated programmes should reflect the forecast start and completion of these activities based on information known at the time, with consideration being provided by the design teams.

Procurement of Long Lead-in Items

Procurement delays can impact project timelines and budgets significantly, particularly for specialist equipment and materials that require a longer time to procure and deliver to the site. Delays in procuring these specialist items can occur with both contractor and owner-furnished items; this can be a lengthy and drawn-out process, particularly where there may be changes within the agreed specifications.

To manage the procurement of long lead-in items, the construction programme should include activities relating to the procurement and delivery of key items. For each progress update, the party responsible for procuring long-lead items should regularly discuss the anticipated delivery dates with its supply chain. Where there are delays in procuring these items, appropriate mitigation measures should be considered to minimise the impact of delay. These discussions should be undertaken just before any agreed reporting dates so updated information can be incorporated within the reporting programme.

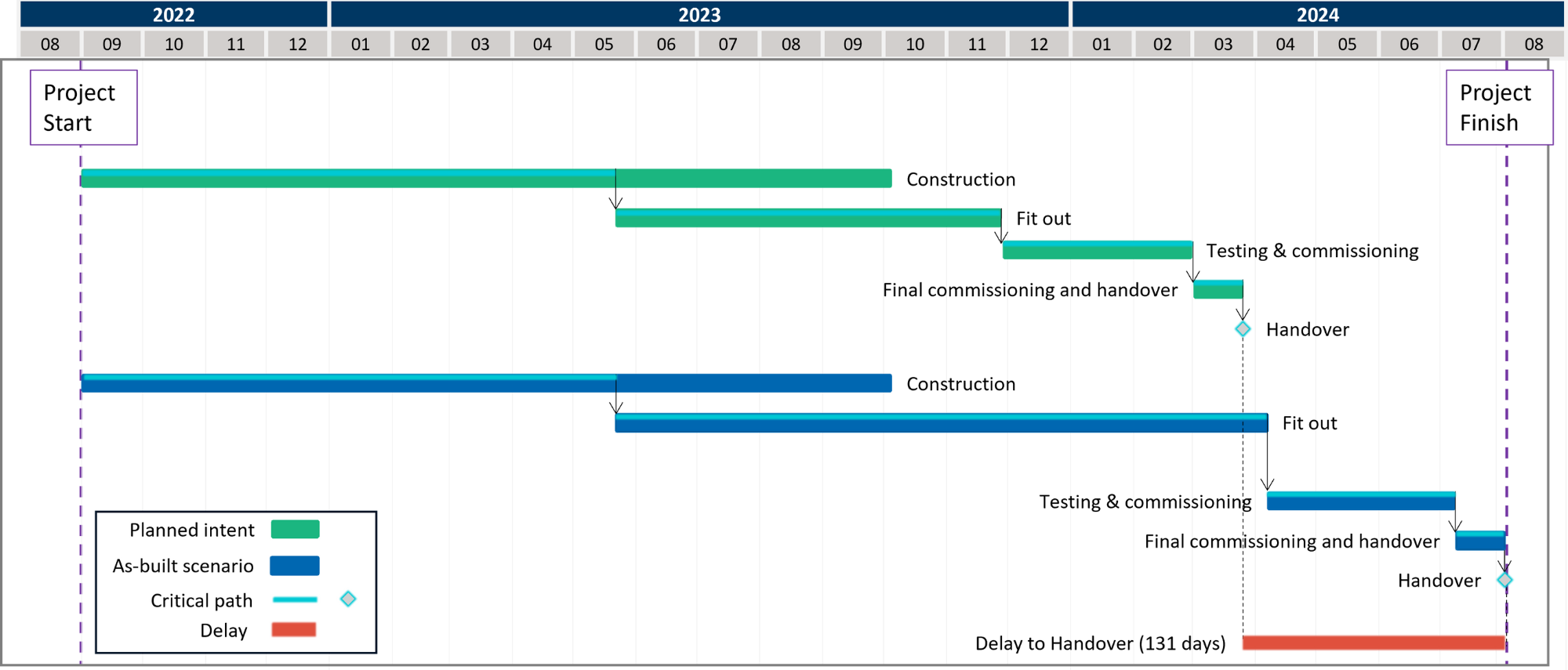

Figure 1 illustrates a simplified, high-level set of programme activities for a data centre that experienced a 131-day delay to the project handover. The planned construction is shown by the green bars and the actual completion of the corresponding activities is shown by the blue bars.

Figure 1 - Simplified, High-Level Set of Programme Activities for Data Centre Delayed 131 Days to Handover

Illustration showing a high-level planned intent of construction activities, corresponding as-built activities, the delay experienced and the critical path for a data centre delay that FTI Consulting advised on.

With only the construction activities included in the planned intent, the delay is shown to have been caused by the prolongation of the fit-out works. However, the simplistic, high-level nature of this planned intent does not clearly demonstrate any reasons as to why this activity was delayed and it does not identify any activities that had potentially caused this delay.

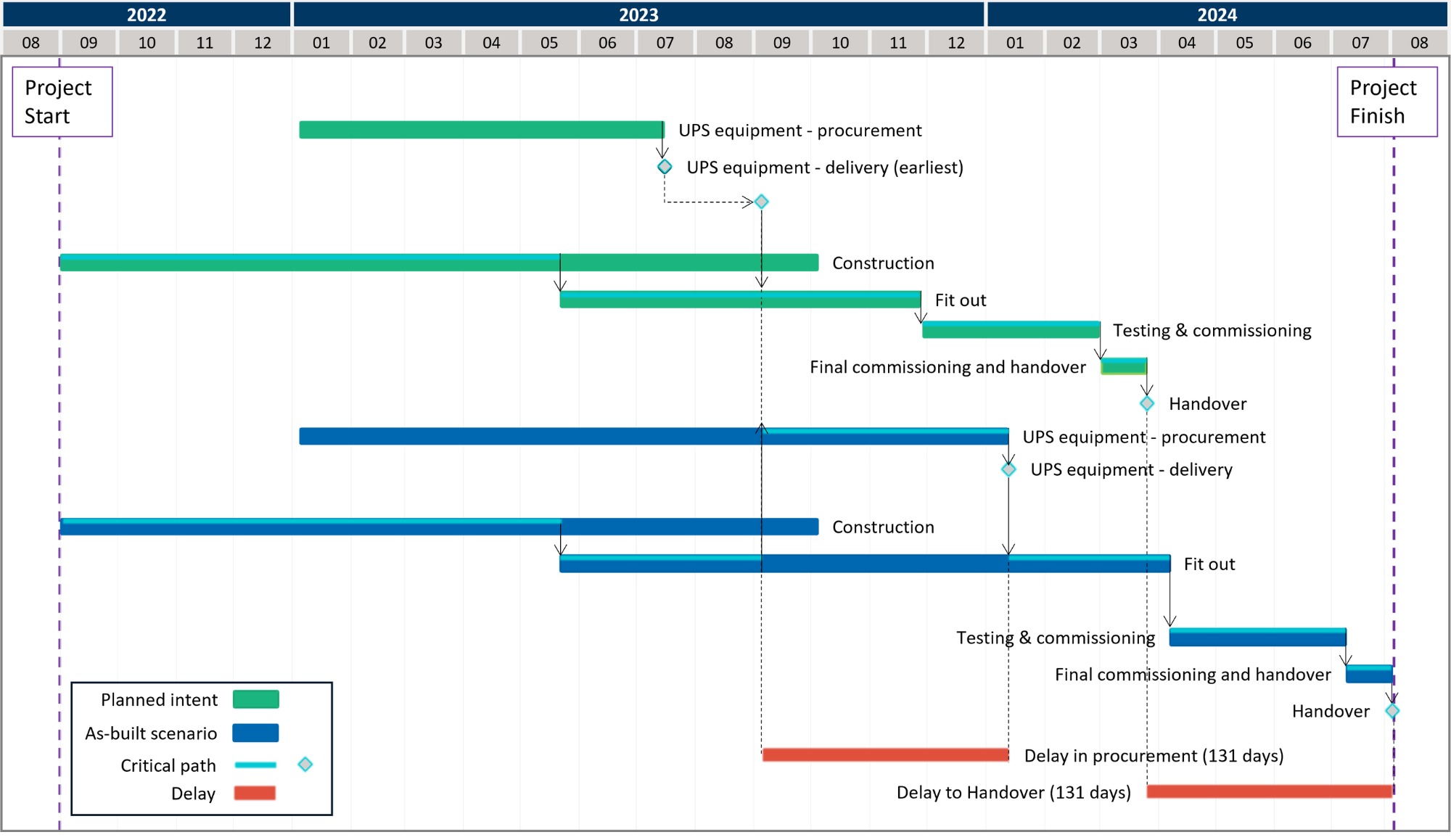

In adopting further detail within the planned intent, the drivers for the delay can be made clearer. Figure 2 expands on the above to include the planned intent and actual scenario for the procurement and delivery of the Uninterrupted Power Supply (“UPS”) equipment. Here, the planned intent for the UPS equipment procurement (shown with the green bars) was not on the planned critical path. However, a prolonged delay of the procurement of this item past the latest date of delivery. Subsequently, the delayed availability of the UPS resulted in a critical delay to the fit-out works (as shown in the shift of the critical path in the blue bars overlayed with red).

Figure 2 - Illustration From Figure 1, With Pre-Construction Procurement Activities Introduced

This shows that if the programme was properly prepared and updated in line with project records, the critical path within the programme would be more informative to accurately reflect the delays that had been occurring contemporaneously.

Supply Chain Management

Managing the supply chain is fundamental to the successful completion of any project. It is of particular importance for data centre projects given the availability of skilled labour and potential access requirements or required clearances.

The supply chain can reduce project risk by undertaking off-site fabrication and delivering pre-assembled equipment or modules overseas.

When constructing a data centre abroad, local approval processes should be considered. Where local sub-contractors need to be engaged to undertake parts of the work, interactions within the supply chain need to respect different work cultures and processes.

To minimise supply chain issues, contractors should:

- Consider and include appropriate risk allowances for local approval processes (if different to the UK).

- Engage suppliers at an early stage of project planning and communicate project timelines, specifications, and expectations by use of the updated programme. This allows the supply chain to better align their production schedules against the planned intent of the contractor’s programme.

- Arrange for individual suppliers to attend progress meetings at regular periods and record forecast dates of key tasks and activities within meeting minutes. Suppliers should be provided with anticipated dates for works that are important to the construction programme.

- Actively pursue and maintain open communication and collaboration between project teams and suppliers. Whilst the contractual obligations of the parties must be maintained, regular engagement and retaining a collaborative approach can help address challenges more effectively.

Whilst each data centre has different demands and there is no one-size-fits-all, the effective management of the supply chain cannot be underestimated.

Development of Programme Activities as the Construction Progresses

Throughout the works, developments due to variations or additional scope can occur, which require the programme activities to be updated.

When updating discrete programme logic and activities, a full review of the programme logic should be conducted to ensure the logic of the original programme still applies.1 Firstly, any changes must be clearly documented and the impact of these evaluated (including an assessment for additional resources). Plans for undertaking approval processes required by regulatory authorities or stakeholders as well as within design standards should be accounted for.

Where the project programme has been set up to incorporate sub-contractor programmes, care should be taken to ensure that these are imported seamlessly. This includes:

- The agreement of the programme calendar.

- Arranging programme activities with unique identifiers to avoid duplication of either the unique activity identifier or activity name.

- Ensure that the correct logic links are introduced between the project programme and the imported sub-contractor programme.

The impact of a variation on a programme can also require a change in sequencing the work, delayed start of key activities or milestones, or additional works. Again, these changes should be documented and included within the programme submission.

The development of a programme as the project progresses is inevitable and care must be taken to document and assess the full impact of any variations, additional scope, or sub-contractor programmes before updating the programme.

Unforeseen Technical Challenges

Technical challenges within data centre projects can arise due to the intricate nature of the facility's infrastructure (both external and internal), systems, power, cooling, and physical security and how all of these work together. For example, there needs to be an uninterruptible power supply and backup generators to function seamlessly on the project in the event of a power failure. There is also the challenge of ensuring that key technical and main equipment rooms achieve different phases of ‘room readiness.’

As a result, it can be common to encounter unexpected technical challenges during the construction process, which can lead to significant delays, despite the most prudent measures and thorough planning that may have been implemented.

The project programme should include milestones for the completion of key work activities so that the cause of a specific delay is transparent to the parties. This could be:

- The completion of key areas (for example, completion of each separate colocation enclosure).

- Sufficiently progressed activities so that the successor activities can commence (for example, weather tightness of an enclosure to start the fit out of key areas).

- Specific elements of the technical/main equipment rooms being ‘room ready’ and in line with the required phases to be undertaken.

The commissioning of data centres can also lead to unforeseen technical challenges as there are more complex and rigorous testing requirements than typical construction projects. It is also important to consider the transition points from contractor-led commissioning to owner-led commissioning. Consideration should be given to the stage at which a detailed commissioning plan is required before introducing this into the programme. The commissioning plan should also be carefully coordinated such that an appropriate number of tagging and witness sign-offs can be achieved over the allocated period.

In preparing the programme appropriately and evaluating the key points related to commissioning, the impact of any unforeseen technical challenges can be more easily identified along the different phases of the works.

Ensuring the Success of Data Centre Construction

The construction of data centres provides several challenges, ranging from commonly occurring issues to those specific to this environment. Notwithstanding the nature of the issues, proper programming and detailed record-keeping are encouraged to minimise the negative repercussions of delays.

To read part one of this series on the key elements of a robust construction programme, click here.

For more information on building a robust construction programme, contact Brijes.Patel@fticonsulting.com

Key Takeaways

- Agree the key dates for pre-construction activities with the client, including design deliverables, design scope and procurement of long-lead items, and regularly monitor these activities.

- Update the forecast dates of the above activities within each progress-updated programme and refer to records of the discussions between the parties that confirmed these dates.

- Engage the supply chain as early as possible and work with each supplier throughout the works.

- Document and fully assess any changes or updates within the originally agreed programme.

- Update the progress-updated programme by first reviewing the current programme and making reasonable amendments and then introducing variations and additional scope. You should be mindful when importing any sub-contractor programmes within the main project programme.

- Include key milestones within the programme and use the relevant milestone to demonstrate the impact of any unforeseen technical challenges.

- Consider the point in time when a detailed commissioning plan is required and ensure the commissioning plan is appropriately sequenced to allow for appropriate inspection and witness sign-offs over the given period.

Footnotes:

1: Recommended under SCL Protocol 2nd edition (2017), paragraphs 1.59 and 1.60 and 1.62.

Related Insights

Related Information

Published

octobre 01, 2024

Key Contacts

Key Contacts

Senior Director