Navigating Global Supply Chain Disruption

The Impact of Bab al-Mandab Strait Instability

-

May 09, 2024

DownloadsDownload Article

-

In recent months, the maritime industry has been grappling with the repercussions of instability in the Bab al-Mandab Strait, causing significant disruptions to commercial shipping vessels traversing the Red Sea. Since mid-November 2023, this instability has persisted, resulting in delays and interruptions in maritime transport along the Bab al-Mandab Strait, a critical passage leading to the Suez Canal. This article delves into the multifaceted consequences of this disruption on the global supply chain, with a particular focus on its implications for the construction industry.

Significance of the Bab al-Mandab Strait and Suez Canal

The Bab al-Mandab Strait holds strategic importance as it serves as the gateway to the Suez Canal, a vital waterway connecting the Mediterranean Sea to the Red Sea. Transit through the Suez Canal offers substantial time savings for vessels traveling between Asia, Europe, and North America.1 However, the ongoing instability in the region has forced cargo vessels to seek alternative routes, leading to increased costs, extended transit times, and potential environmental impacts.

Figure 1 – Bab al- Mandab Strait and Suez Canal location

Figure 1 – Bab al- Mandab Strait and Sue Canal location

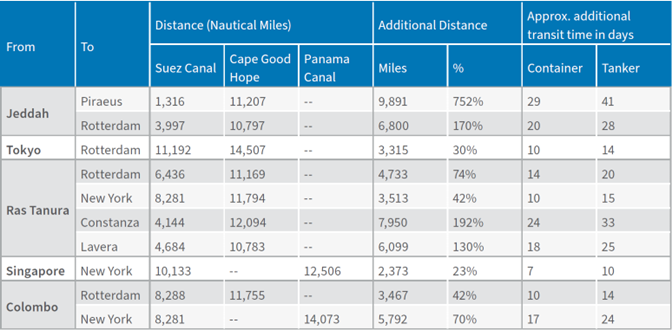

Table 1 – Impact of Re-routing on Shipping Routes

Table 1 – Impact of re-routing on shipping routes

Impact on Global Trade and Freight Costs

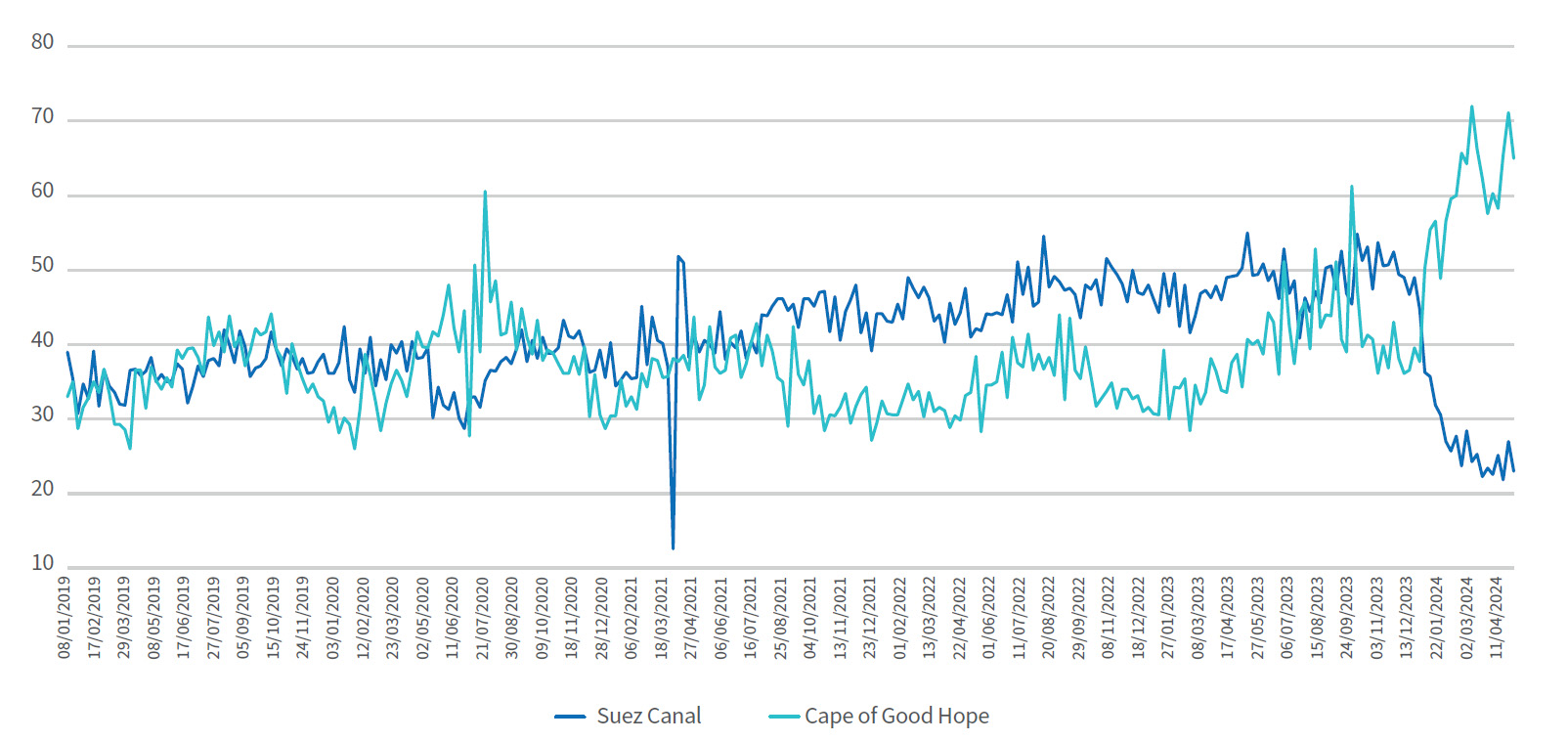

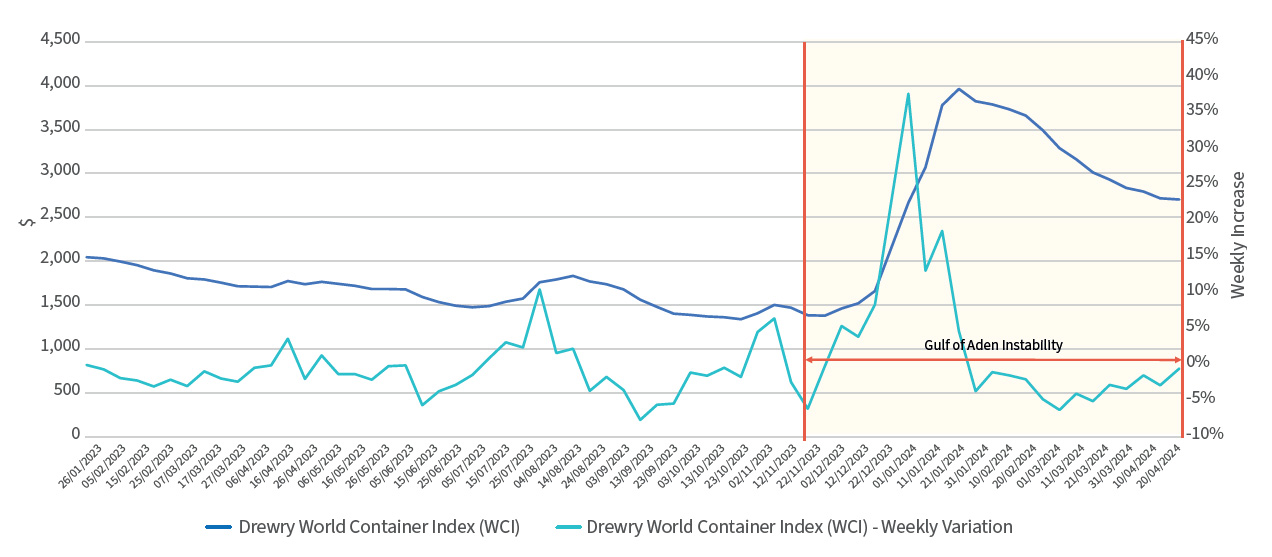

The diversion of cargo ships away from the Suez Canal to alternative routes, such as the Cape of Good Hope, has disrupted global trade patterns. This shift has resulted in increased distances and transit times for shipments, as depicted in Figure 2.2 Consequently, freight costs have surged, as evidenced by the significant uptick in the Drewry World Container Index (WCI) since mid-November 2023, as illustrated in Figure 3.3 The WCI serves as a barometer for changes in ocean freight rates across key maritime routes, highlighting the substantial cost implications of the current disruptions.

Figure 2 – Cargo Ships Transiting Suez Canal vs Cape of Good Hope

Figure 2 – Cargo Ships transiting Suez Canal vs Cape of Good Hope

Figure 3 – January 2023 to April 2024 Drewry World Container Index Trend

Figure 3 – January 2023 to April 2024 Drewry World Container Index Trend

Historical Context and Previous Events

The challenges facing the Suez Canal and surrounding regions are not unprecedented. Historical events such as piracy activity in the Gulf of Aden, the global freight disruptions caused by the Covid-19 pandemic, and the blockage of the Suez Canal by the Ever Given container ship in March 2021 have all contributed to instability in maritime trade routes. These events underscore the vulnerability of global supply chains to unforeseen disruptions.

Anticipated Impact on Construction Projects

The construction industry, heavily reliant on timely delivery of materials and equipment from global suppliers, is particularly vulnerable to disruptions in the maritime supply chain. Key sectors such as solar panel manufacturing, industrial equipment production, and semiconductor materials are expected to face challenges due to disruptions in the supply chain. The reliance on Chinese production for solar panels and industrial equipment, coupled with dependencies on global suppliers for critical materials, poses significant risks to construction projects worldwide.

Mitigation Strategies and Recommendations

In response to the current challenges, contractors must proactively assess the potential impact on their projects and implement mitigation strategies. This includes evaluating alternative transportation methods, such as air freight, although cost considerations may limit its feasibility. Local manufacturing may offer some respite; however, logistical constraints and production costs must be carefully weighed.

Tailoring a specific mitigation strategy will depend on the nature of the project. Ideally, risk avoidance, such as sourcing materials from routes unaffected by the current situation or shortening the supply chain, stands as the primary mitigation approach. However, the feasibility of alternatives may vary. Further mitigation measures stem from contractual compliance and regional laws. Contractor should maintain transparent records of the impact on their projects and adhere to contractual obligations regarding notification and claims processes. Such adherence may offer relief to contractors in terms of performance. Additionally, contractors should examine applicable regional laws to seek potential relief from additional costs and delays induced by the current situation, which could affect the economic equilibrium of the contract.

Finally, effective communication among all stakeholders to share an understanding of the consequences is essential for navigating supply chain disruptions. Collaborative efforts among contractors, employers and suppliers will be crucial for minimizing delays and mitigating the adverse effects on construction projects.

Conclusion

The instability in the Bab al-Mandab Strait has cast a shadow over global maritime trade, with far-reaching implications for the construction industry. As the situation continues to evolve, contractors must remain vigilant and proactive in managing supply chain risks. By implementing robust mitigation strategies which would depend on the nature of the project, effective contract management, applicable regional laws related to hardship and fostering collaborative relationships, stakeholders can navigate these challenges and ensure the resilience of construction projects in an uncertain global landscape.

Published

May 09, 2024

Key Contacts

Key Contacts

Senior Director

Senior Director

Consultant

Downloads

Most Popular Insights

- Beyond Cost Metrics: Recognizing the True Value of Nuclear Energy

- Finally, Pundits Are Talking About Rising Consumer Loan Delinquencies

- A New Era of Medicaid Reform

- Turning Vision and Strategy Into Action: The Role of Operating Model Design

- The Hidden Risk for Data Centers That No One is Talking About